Controlling Costs When HVAC Equipment Fails

Should Your Repair or Replace a Broken AC Unit?

When an out-of-warranty air conditioning system fails, the cheapest fix may not be the most cost-effective. There is a point of diminishing returns and, finding that point could save you time and money. There are several factors to consider.

Age, Condition, and Remaining Warranty

An HVAC system should last between 9 and 15 years with proper maintenance. If the unit is less than 9 years old, but is no longer covered under warranty, you must carefully weigh the cost of the repair needed with the anticipated life expectancy after the repair.

In addition to the cost of the part(s) that need to be replaced, you will want to factor in the available warranty on those parts, the remaining life expectancy of the parts not to be replaced, and of the unit itself. For example, putting a brand new compressor into a unit with an aging blower or air handler that cannot be expected to last more than a few more years would probably be unwise.

Cost of Materials to Repair Versus a New Unit

Parts – the cost of replacement parts will be the first consideration. Can you expect to get enough life out of the replacement compressor to recuperate the cost before the rest of the unit must be replaced?

Refrigerant – when calculating the cost of a repair, do not forget to factor in the cost of refrigerant. Depending on the refrigerant that you use, this could be from $25-$50 per pound and you will need about 7 lbs when installing a new compressor.

Replacement – Before making a major repair to an HVAC unit that is approaching a decade in use, take the time to price out the options to replace the whole unit. Illustrated below is a slightly cheaper and less labor-intensive alternative. Instead of replacing the entire unit, consider replacing the condenser and air handler coil. Many times, this will leave you with a virtually new system more easily and more economically than a full replacement. If the unit is in a cramped space or has ductwork that might not align easily with an entirely new system, this may be your best option.

Labor Required

Before making any decision, you should factor in the costs of the time and effort to repair a unit or to install a new system. To most maintenance techs, the initial cost savings of replacing just a bad compressor does not justify the time and labor it requires.

To pull a failed compressor from a condensing unit, the tech much reach into the cage, disconnect and then pull the heavy compressor out of the unit. Replacing with a new unit and making the new connections bent over the cage is not an easy undertaking. This is hard for most technicians physically and, when trying to match connections between the old and new compressor, with limited access and visibility inside the condenser, it can be a difficult, time-consuming job.

Unless the compressor is under warranty inside a system that still has most of its life expectancy, just replacing the compressor may be the cheapest fix but it will be difficult and is likely not the most economical option.

Formula:

To calculate the cost of a repair versus a new system over time, all of these factors must be taken together. The two-part formula to consider would look something like this:

(Parts + Refrigerant)

+(Labor x Hours)

= Repair Costs

Repair Costs

÷ Expected Lifespan

= Cost Per Year

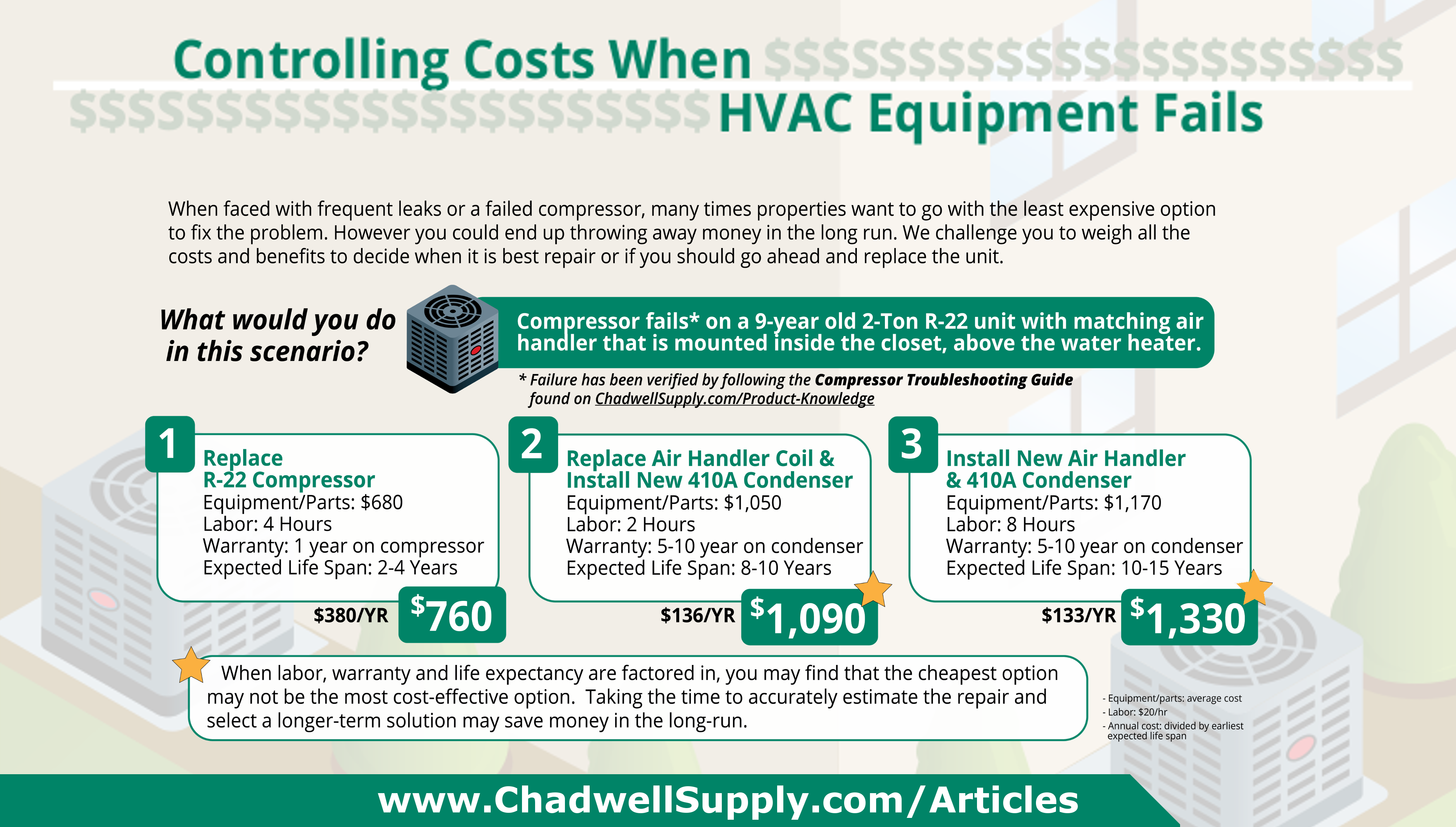

The illustration below uses the example of a failed compressor in a 9 year old R-22 HVAC system to explain these factors.

The Scenario and Options to Consider

*Failure has been verified by following the Compressor Troubleshooting Guide.

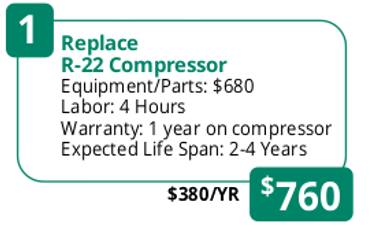

Option 1: Replace the Compressor

You can simply replace the R-22 compressor for about $700. But when you factor in the labor costs of this very difficult job and then divide the result by the 2-3 year life expectancy of the overall system, your annual cost would be $380 with only a one year warranty on the compressor.

Option 2: Replace the Air Handler Coil & Install a New Condenser

Rather than simply replacing the failed R-22 compressor, you could replace the condenser with a 410A unit and the air handler coil with a 410A compatible coil. The equipment cost for this job would be more, approximately $1,000 but the new condenser comes with refrigerant and the labor costs (and level of difficulty) would be considerably less. With this more expensive route, you will see a life expectancy of as much as 8-10 years with a 5-10 year warranty on the condenser itself (depending on the manufacturer). With the extended lifespan, you have an annual cost of only $136 with the added benefit of the new warranty on the condenser.

Option 3: Install a New System (Air Handler and Condenser)

If your budget allows, to stave off future repairs and start over with a fresh warranty, by replacing the whole system. The cost would be a bit more, approximately $1,200 and the time to complete the job is considerably more, especially in a tight space where installation could be difficult. However, the life expectancy on that new unit is 10-15 years, making your annual cost only $133 plus the 5-10 year warranty on the system.

In multifamily, we all have to work within budgets and you have likely not budgeted to replace a nine year old HVAC system. Unfortunately, depending on maintenance of that system over the years and the extent of use, when it begins to fail, you have a tough decision to make. While you didn’t plan on a full replacement, pushing that expense off for a couple of years could actually be much more expensive.

If you are looking to make the most fiscally responsible decision and need to make the case for this unexpected expenditure, Option 2, replacing the condenser and the A-coil with 410A compatible parts, may be the right decision for you.

This is just one example. We cannot know all the budgetary and logistical factors that you may need to consider. Many of our local Chadwell Supply associates have years of HVAC experience and/or experience managing a complicated multifamily housing budget. Your local representative also has access to the collective wisdom and experience of our whole team and is ready and willing to help you make the very best decision for your property when faced with the question: “should I repair or replace this HVAC system?”