Multifamily teams are weighing the benefits of sticking with R-410A or changing to A2L rated equipment. Step one is to inventory equipment to determine how long that equipment will likely remain in service.

How Healthy Is Your HVAC? An HVAC Inspection Checklist for the R-410A → A2L Transition

Why 2025 Is the Inflection Point

The transition to new, low-GWP (Global Warming Potential) refrigerants is officially underway. With the production of R-410A refrigerant reduced by 40% and restrictions on new R-410A equipment sales and installation set to take effect at the end of 2025, now is the time to assess the health of your HVAC systems. These rules affect new HVAC installation across split system and air conditioning system classes as portfolios migrate toward low-GWP refrigerants.

A proactive HVAC inspection will help multifamily teams avoid last-minute surprises, manage budgets more effectively, and ensure uninterrupted comfort for their residents. That means apartments are consistently heated and cooled to target temperature and humidity—key for comfort and indoor air quality.

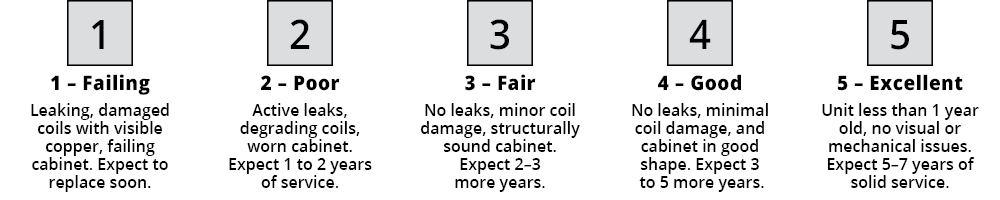

Getting ahead of the transition means knowing which units are in great shape, which can provide good service for a few more years, and which are headed for replacement.

Key Takeaway: A standardized HVAC inspection turns guesswork into a roadmap—catch leaks early, score each unit 1–5, and plan R-410A → A2L replacements on your timeline to avoid supply and scheduling crunches.

Start with an HVAC Equipment Review

The HVAC experts at Chadwell Supply have developed a simple, effective Refrigerant Transition Checklist. This guide helps you evaluate the condition of every unit on your property. Use this tool to help make informed decisions about what to replace and when. Capture model/serial for HVAC equipment, note ventilation and air conditioning pathways, and label the indoor and outdoor sections of each cooling system.

Equipment Check: What to Look For!

Just because a unit has some years on it, does not necessarily mean it needs to be replaced. Here are some signs that it probably does:

- Visible leaks

- Failing coil fins

- Damaged, rusted, or deteriorating cabinet

- Clogged air filters restricting airflow and degrading indoor air quality

- Blocked outdoor air intake or debris around the outdoor condenser

- Out-of-range temperature and humidity at supply vents (insufficient cool air)

What should I look for during an HVAC inspection?

Check coils, cabinets, electrical/controls, airflow, drainage, and leaks. Photograph issues and document findings consistently. Score each unit 1–5 so budgets and timelines reflect actual condition—not guesses. Include the air handling unit, confirm indoor and outdoor fan operation, and verify split system charge/performance on the air conditioning system.

Equipment Condition: Maintain, Repair, or Replace?

Use this simple rating scale to evaluate the lifespan of every single HVAC unit on your property:

Refrigerant Leak: Repair or Replace?

Even if a unit is still working, every refrigerant leak should be addressed as soon as possible. Federal laws regulate when and how leaks should be addressed, and property managers also have guidelines their maintenance technicians should know and follow. Leaks reduce cooling system capacity—supply registers may deliver less cool air, and runtimes increase.

Preventive maintenance is the most effective way to catch small leaks before they become big, expensive problems. Simplify annual maintenance tasks with Chadwell Supply’s HVAC Maintenance Checklist. Property managers should include air filters replacement, coil cleaning (AHU and outdoor condenser), and checks of temperature and humidity sensors.

Small Leaks

(about 1–2 pounds per year)

These are often found on the suction vapor side. You may be able to address the issue with a stop-leak product like A/C Leak Freeze Pro (#107212)

Moderate Leaks

(about 1–2 pounds every 6 months)

This may indicate issues with the evaporator distributor tubes. A stop-leak product might still be effective. If not, locate the leak and weld the leak.

Significant Leaks

(about 1–2 pounds every 3 months)

This suggests a liquid line or condenser leak. Look for oil stains to help locate the issue. You’ll need to repair the leak or replace the condenser.

How do I decide to repair or replace after a refrigerant leak?

Log leak rate and location. Small, isolated leaks may be repaired; recurring or significant leaks often justify replacement—especially as you standardize on low-GWP A2L equipment. Factor the age of the HVAC system, availability of parts for your split system, and upcoming HVAC installation timelines.

These leak tips are meant to be general guidelines. Certified HVAC technicians on-site should evaluate equipment fitness based on that unit’s specific condition.

Fewer Surprises: Better Preparation!

Perform this check on every HVAC unit on your property. The goal isn’t to predict the exact moment a unit will fail. The idea is to have a realistic snapshot of your HVAC inventory's current health. Every mechanical system has a lifespan. Staying ahead of eventual equipment failure means fewer expensive and time-consuming surprises. These time and budget savings are even more important as the residential HVAC industry shifts to A2L rated equipment and refrigerant. Routine checks across heating ventilation and air systems ensure balanced ventilation and air conditioning—so spaces stay properly heated and cooled.

Accurate Snapshot: What’s Next?

If your HVAC equipment inventory reveals units need to be replaced, contact your Chadwell Supply representative. We’re ready to support your team and your property with the equipment, tools, and knowledge needed to keep your residents comfortable and your HVAC systems running strong. We can advise on central systems, PTACs, and even window air conditioner replacements where appropriate, plus AHU upgrades for better indoor air quality.

FAQs

What’s the R-410A install deadline?

New high-GWP systems assembled from components manufactured or imported before January 1, 2025, may be installed only through December 31, 2025. New installations after that must meet low-GWP thresholds. This includes many air conditioning system classes and common split system installs.

Are repairs on existing R-410A systems restricted?

No. Components used to repair existing systems are treated differently from new-system installations. Follow EPA Section 608 for leak repair and recordkeeping. That allows continued servicing of legacy HVAC equipment while you plan transition steps.

Why are refrigerant supplies tighter?

HFC allowances are stepping down nationally, reducing available supply and encouraging adoption of lower-GWP alternatives. Plan refrigerant stock for both the cooling system and any backup air handling unit service needs.

How much does HVAC maintenance cost for multifamily portfolios?

HVAC maintenance cost varies by climate and portfolio size. Budget for filters, coil cleaning, tune-ups, and refrigerant leak repair. Use inspection scores to plan replacements and control spend.

How do I get the checklist and start?

Download the Refrigerant Transition Checklist, then contact your local rep for an inventory review. We’ll align inspections with temperature and humidity targets, air filters schedules, and HVAC installation timelines.